How to Choose the Right Materials for Your Office Furniture Project: A Complete UAE Materials Guide

Walking into an office space tells you everything about a company before anyone says a word. The desk materials, the chair upholstery, even the finish on conference tables, all communicate something. Are you stepping into a place built to last, or somewhere cutting corners?

If you’re planning an office furniture project in the UAE, you’re probably drowning in material options. Solid wood or engineered boards? Metal frames or wooden legs? HPL surfaces or natural veneer? These aren’t just aesthetic choices—they’re investments that affect your bottom line for years.

Here’s what makes material selection tricky in Dubai and the broader Middle East: you’re dealing with extreme climate conditions, high expectations for quality, and a market that demands both durability and visual appeal. Your furniture needs to survive intense heat, occasional humidity, and constant use while still looking sharp for client meetings.

This materials guide breaks down everything you need to know about choosing the right office furniture materials for your workspace—from traditional wood options to modern composite surfaces like Corian and premium engineered boards. We’ll cover what works best in different office zones, how manufacturing choices affect your final product, and what sustainability really means beyond the buzzwords.

Let’s start with why material choice matters more than most people realize.

Why Material Choice Matters in Office Furniture Manufacturing

Think about your office furniture like a long-term relationship—you’re committing to live with these choices for at least five to ten years. Pick the wrong partner (or material), and you’ll pay for it daily.

Durability is your first concern. Office furniture takes a beating. Desk surfaces handle coffee spills, laptops, sharp objects, and constant elbow pressure. Conference tables host daily meetings with people leaning, writing, and occasionally dropping things. If you choose materials that can’t handle this punishment, you’ll see scratches, chips, and wear marks within months.

Appearance shapes your brand identity. Materials communicate your company’s values without saying a word. Rich walnut veneer in an executive suite suggests tradition and stability. Sleek glass and aluminum in an open workspace signals innovation and transparency. The materials you choose become part of your brand story.

Cost efficiency extends beyond the price tag. Sure, that particleboard desk costs less upfront than solid oak, but what about three years from now when the edges are chipped and the surface is delaminating? Total cost of ownership includes the initial investment, maintenance expenses, and eventual replacement.

Regional conditions demand specific considerations. The UAE presents unique challenges. High temperatures, occasional humidity spikes, intense sunlight through office windows, and sandy conditions all affect material performance. Wood that works perfectly in London might warp in Dubai. This is why manufacturers like Skymoon Furnitures in Dubai carefully select materials proven to perform in Middle Eastern conditions.

Material Selection Criteria for Office Furniture Projects

Before you fall in love with that gorgeous teak finish or modern concrete-look laminate, step back and evaluate systematically.

Durability and Life-Cycle Performance

Office furniture faces relentless use. A typical office desk sees action for eight to twelve hours daily, five days a week—that’s over 2,500 hours annually. High-traffic areas like reception desks and shared workstations endure even more punishment.

Ask yourself: Will this material still look presentable after three years of constant use? Can it handle impacts, scratches, liquid spills, and cleaning chemicals?

Aesthetic and Brand Alignment

Your office furniture should tell your company’s story. A law firm might choose rich wood tones and traditional materials to convey authority. A tech startup might opt for light-colored laminates with metal accents to project innovation.

Consider how materials will photograph too. In our social-media-driven world, meeting rooms and executive spaces often appear in marketing materials. Materials that look flat or cheap on camera can undermine your brand image online.

Cost Efficiency and Total Cost of Ownership

Budget constraints are real, but the cheapest option rarely delivers the best value. A reception desk in quality engineered wood with durable laminate might cost more initially than a particleboard alternative, but if it lasts twice as long and maintains its appearance, the investment makes financial sense.

Environmental and Regulatory Aspects

Sustainability isn’t optional anymore—it’s expected. Look for materials with recognized certifications:

- FSC or PEFC certification for wood products (ensures responsible forestry)

- E0 or E1 ratings for engineered wood boards (indicates low formaldehyde emissions)

- Low-VOC finishes that don’t release harmful chemicals

Brands like EGGER from Germany have set industry standards for environmental certifications, making them a benchmark for quality engineered wood products.

Regional Environmental Factors

The UAE’s climate is not kind to furniture. Intense heat, varying humidity levels, and sandy conditions create specific challenges. Materials need proper moisture content adjustment, UV-resistant finishes, and smooth surfaces that resist dust accumulation. Manufacturers operating in Dubai understand these regional nuances intimately.

Wood Materials: The Foundation of Office Furniture

Wood remains the foundation material for quality office furniture. It’s versatile, durable, repairable, and carries an inherent sense of quality. But “wood” covers a wide spectrum of options.

Solid Wood Options

Solid wood represents the premium tier. Oak offers strength and prominent grain patterns, perfect for executive desks. Walnut brings darker, richer tones that communicate luxury. Maple provides hardness for high-use surfaces with its light, neutral color. Beech offers solid wood benefits at more accessible pricing.

The challenge? Cost and weight. A full solid wood desk can be prohibitively expensive. That’s where engineered solutions shine.

Engineered Wood and Premium Wood Boards

Engineered wood products deliver wood’s aesthetic appeal at more accessible prices:

Plywood: Multiple thin layers of wood veneer glued with alternating grain directions. This provides excellent strength and dimensional stability. High-quality plywood resists warping better than solid wood while weighing less.

MDF (Medium-Density Fiberboard): Made from wood fibers compressed with resin. MDF offers a perfectly smooth surface that takes paint and veneer beautifully. It’s heavier than plywood but provides a flawless base for high-quality finishes.

Premium Engineered Boards: Companies like EGGER have revolutionized this category. EGGER boards from Germany are known for their consistent quality, low emissions (E1 and E0 ratings), and extensive design options. These boards form the core of much modern office furniture manufacturing, offering reliability and performance that meets stringent European standards.

Particleboard: The most economical option, suitable for low-stress applications like low-height cabinet shelves, but avoid it for primary work surfaces where durability matters.

Veneer Finishes Over Engineered Boards

Here’s where smart manufacturing creates value: apply a thin layer of real wood veneer over a stable engineered core, and you get wood’s beauty with better performance and lower cost. A veneered plywood panel looks identical to solid wood but costs 40-60% less and won’t warp over time.

Quality veneer work makes all the difference. Premium furniture uses thick veneer (0.6mm or more) with proper edge banding that can be refinished if damaged.

Wood Treatment and Certification

Not all engineered boards are equal. Moisture content needs proper acclimatization to local humidity levels before fabrication—crucial in the UAE’s climate. Formaldehyde emissions matter for indoor air quality, which is why E1 and E0 ratings are essential specifications.

Look for FSC or PEFC certifications indicating wood from responsibly managed forests. These aren’t just environmental badges—certified sources often indicate higher quality overall.

Other Key Material Categories

Modern office furniture relies on a carefully orchestrated mix of materials beyond wood.

Metal Structures and Frames

Metal provides the structural backbone for today’s office furniture:

Steel frames offer maximum strength for minimal thickness. Powder-coated steel resists scratches and corrosion while supporting heavy loads. You’ll find it in workstation desk frames and filing cabinets.

Aluminum weighs significantly less than steel while maintaining good strength. It naturally resists corrosion, making it ideal for the UAE climate. Aluminum works beautifully for modern designs where visible metal becomes a design feature—conference tables with aluminum legs, reception counters with brushed aluminum trim.

Laminates and Engineered Surfaces

High-pressure laminate (HPL) has revolutionized office furniture manufacturing. It consists of multiple layers of kraft paper saturated with resin, topped with a decorative layer, all compressed under high heat and pressure.

Modern laminates can convincingly mimic wood grain, stone textures, or solid colors. A well-executed wood-grain laminate can fool most people at typical viewing distances. The practical benefits are substantial: consistent color, easy maintenance, stain resistance, and lower cost than natural materials.

For conference tables that see heavy daily use, HPL often outperforms real wood in durability. It won’t scratch from laptop movement or water-stain from condensation rings.

Solid Surface Materials: Corian and Similar Products

Corian represents a premium category of solid surface materials. Made from acrylic polymer and natural minerals, Corian offers unique advantages for office applications:

Seamless appearance: Joints between sections are virtually invisible when properly fabricated, creating continuous surfaces perfect for reception desks or executive work surfaces.

Durability: Corian resists stains, is non-porous (doesn’t harbor bacteria), and minor scratches can be sanded out. This repairability extends furniture life significantly.

Design flexibility: Corian can be thermoformed into curved shapes, creating distinctive modern designs impossible with traditional materials.

Color consistency: The color runs throughout the material, so chips or scratches don’t expose a different substrate color underneath.

While Corian costs more than laminate, its durability and premium appearance justify the investment for high-visibility applications like reception areas or executive suites. It’s particularly popular in Dubai’s luxury office market where design sophistication matters.

Glass and Transparent Materials

Glass brings openness and modernity to office spaces. Tempered safety glass is standard—four to five times stronger than regular glass. It works beautifully for conference table tops, reception desk transaction surfaces, and display cabinets.

The UAE market particularly appreciates glass for keeping spaces feeling open while managing intense exterior light. Frosted or tinted glass provides privacy without creating a closed-off feeling.

Upholstery Materials

Office seating and soft zones require careful textile selection:

Commercial-grade fabrics use tight weaves and synthetic fibers for durability. Look for fabrics rated for 30,000+ double rubs on the Martindale test. In the UAE, stain-resistant treatments help furniture survive daily wear.

Leather communicates luxury and ages gracefully. Top-grain leather develops a patina over time, justifying its expense for executive seating.

High-quality vinyl offers excellent durability and easy cleaning at a fraction of leather’s cost. Modern vinyl has evolved far beyond cheap plastic—it’s ideal for high-use areas with budget constraints.

Matching Materials to Office Zones and Use Cases

Strategic material selection means putting premium materials where they matter most and using cost-effective solutions where they make sense.

Executive and Boardroom Zones

These spaces represent your company to clients and partners. Material choices should communicate success and permanence:

Best materials: Solid wood or high-quality veneer for desks and tables, Corian or premium laminate for work surfaces, premium leather for seating, glass accents for modernity. An executive desk might feature walnut veneer over EGGER board core with solid wood edge banding—visually stunning but properly engineered.

Open-Plan Workstations

Functionality and durability trump prestige here:

Best materials: EGGER boards or similar premium engineered cores with durable HPL surfaces, powder-coated steel frames, commercial-grade fabrics for seating. A workstation desk system using quality engineered board with laminate surface handles daily wear, resists scratches, and maintains appearance for years.

Reception and Lobby Areas

Your reception area is your company’s handshake. It needs to impress without being extravagant:

Best materials: Mix of premium and practical. A reception desk might feature wood veneer or Corian facing with laminate on the service side, glass transaction surfaces, and metal accents. These combinations balance aesthetics with serious durability requirements.

Break-Out and Collaborative Zones

These flexible spaces support casual meetings and collaborative work:

Best materials: Lighter-duty options work here. Laminate surfaces on tables, simpler metal frames, colorful fabrics that inject personality. Materials can be more playful and less formal while still needing reasonable durability.

Climate-Specific Considerations for the UAE

Every material choice in the UAE should consider environmental factors. Heat tolerance matters—avoid materials that off-gas when heated. Properly sealed wood prevents moisture absorption. UV-resistant finishes protect against sun damage. Smooth, sealed surfaces clean more easily than textured materials in dusty conditions.

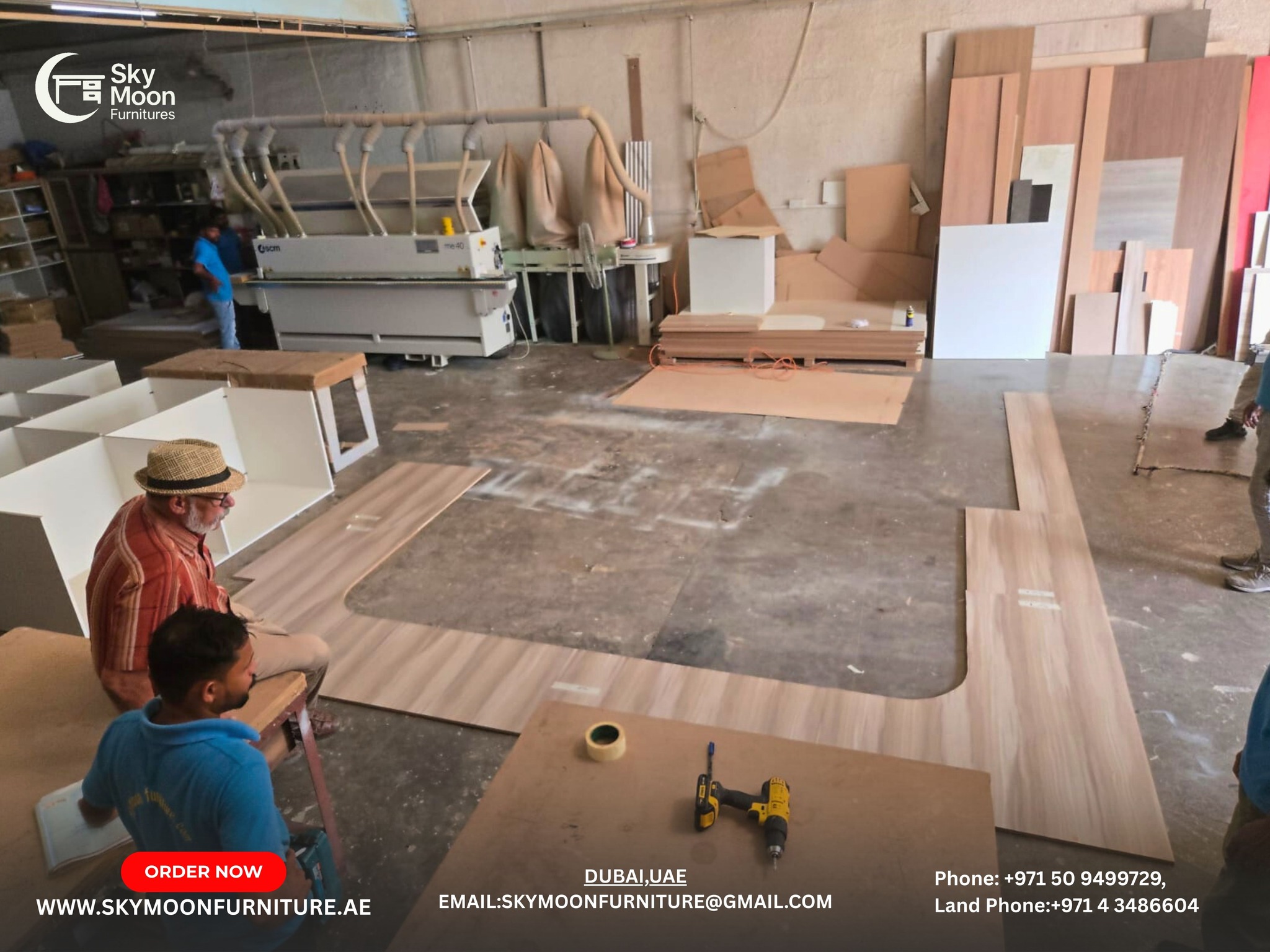

Manufacturers like Skymoon Furnitures who operate in Dubai understand these regional considerations instinctively through years of experience.

Manufacturing and Supply Chain Considerations

Material selection directly affects how your furniture gets made, how long it takes, and what it costs.

How Materials Affect Manufacturing Processes

Different materials demand different fabrication approaches. Wood and engineered boards require CNC cutting, edge banding, and drilling. Quality edge banding should be seamless and durable. Metal components need cutting, welding, and powder coating. Solid surfaces like Corian require specialized fabrication skills and equipment.

Complex designs mixing multiple materials increase fabrication time and cost. A simple pedestal drawer unit in laminate-covered board manufactures quickly. A desk combining wood veneer, Corian elements, and metal details requires coordination across multiple production stages.

Lead Times and Material Availability

Common materials like standard laminates and EGGER boards ship quickly. Manufacturers maintain stock of frequently used materials. Special-order materials like exotic wood veneers, custom Corian colors, or imported fabrics can add weeks to lead times.

Dubai’s position as a trade hub provides access to materials from Europe, Asia, and beyond. However, global supply chain factors can affect delivery. Experienced manufacturers maintain relationships with multiple suppliers and keep buffer stock of critical materials.

Finishing and Lifecycle Management

How materials age affects total cost of ownership. Laminates need only occasional cleaning. Wood requires more careful maintenance. Corian’s repairability—minor damage can be sanded and polished out—extends furniture life significantly. Quality furniture should allow repairs rather than requiring full replacement.

Some materials improve with age—leather develops patina, wood deepens in color. Others just look worn—cheap laminate peels, thin veneer can’t be refinished.

Sustainability, Certifications, and Future Trends

Environmental responsibility has moved from nice-to-have to essential in corporate procurement decisions.

Eco-Friendly Materials and Certifications

Sustainable materials serve both ethical and practical purposes:

Wood certifications: FSC and PEFC verify responsible forestry. EGGER, for example, has been a pioneer in sustainable wood-based panel production, with extensive FSC and PEFC certifications across their product lines.

Low-VOC emissions: E0 and E1 ratings limit formaldehyde off-gassing, crucial for indoor air quality in enclosed office environments with recirculated air conditioning.

Recycled content: Some laminates and metal components now incorporate recycled materials without compromising performance. Aluminum is infinitely recyclable.

Modularity and Future-Proofing

Sustainable furniture design emphasizes adaptability. Modular components allow reconfiguration as office needs change. Workstation systems that can be reconfigured reduce waste and cost. Replaceable parts extend furniture life—if a drawer track fails, replacing just that component beats scrapping the entire unit.

Future Material Trends

Watch for bio-based materials, carbon-neutral manufacturing, circular economy thinking, and smart materials with antimicrobial properties. Expect increasing demand for material origin documentation and supply chain transparency.

Budgeting and Total Cost of Ownership

Smart procurement looks beyond purchase price to true lifetime costs.

Estimating Total Cost of Ownership

Calculate the complete financial picture including initial investment, maintenance costs, repair frequency, replacement timeline, and residual value.

Example: A quality executive desk at AED 8,000 lasting 15 years costs AED 533/year. A budget desk at AED 3,500 replaced every 5 years costs AED 700/year. The premium approach delivers comparable or better annual costs while providing superior appearance and functionality.

Building the ROI Argument

Present material decisions in business terms. For facility managers, emphasize reduced maintenance and fewer replacement projects. For HR departments, connect furniture quality to employee satisfaction. For owners and CEOs, frame choices around brand impact and client perception.

Common Mistakes in Material Selection

Learn from expensive mistakes others have made:

Choosing cheapest without considering suitability. Match material quality to application demands, not just budget constraints.

Ignoring local climate. Material specifications from European projects don’t automatically transfer to Dubai’s environment.

Over-specifying premium materials. Don’t waste budget on materials in low-traffic zones nobody will notice.

Not verifying quality and certifications. That claimed “E1-rated board” might not meet standards without verification. Insist on documentation.

Neglecting edge details and hardware. Beautiful surface materials paired with cheap edge banding or flimsy hardware ruins quality perception.

Material Selection Checklist

Use this systematic approach:

- Purpose and zone: What’s the primary function and location?

- Usage intensity: How many hours daily? How many users?

- Brand requirements: What image should furniture project?

- Budget constraints: Total project budget and lifecycle considerations?

- Performance needs: Required durability, maintenance level, special properties?

- Climate factors: Sunlight exposure, temperature, humidity, dust?

- Manufacturing capacity: Can your manufacturer work with these materials effectively?

- Sustainability: Required certifications? Environmental goals?

- Lead time: Realistic timeline for sourcing and fabrication?

- Maintenance: Required cleaning and care procedures?

Making Confident Material Decisions

Choosing the right materials for your office furniture project balances durability, aesthetics, cost, and sustainability for your specific needs.

Remember these key points: Match materials to zones and usage patterns. Calculate total cost, not just initial price. Respect the UAE climate by choosing proven materials. Balance brand image with practicality. Don’t overlook sustainability—environmental credentials matter to stakeholders.

The most successful projects start with clear material specifications developed through collaboration with your manufacturing partner. Early consultation helps identify potential issues, optimize selection for your budget, and ensure realistic timelines.

Ready to make informed material decisions for your office project?

At Skymoon Furnitures, we’ve been manufacturing quality office furniture in Dubai for years, working with the full spectrum of materials from solid wood to premium engineered boards like EGGER, modern solid surfaces like Corian, and contemporary laminates. We understand the UAE climate challenges and how to balance aesthetic aspirations with practical budgets.

Whether you’re planning a complete office fit-out or updating specific areas, we can guide you through material selection based on your actual needs—not just what’s most expensive or currently trendy.

Contact us to discuss your project. We’ll help you choose materials that work for your space, your budget, and your timeline. Or explore our range of customization options to see how different materials can be combined to create furniture that’s uniquely yours.

Your office furniture is an investment in your company’s daily operations and long-term success. Make material choices that serve you well for years to come.

Frequently Asked Questions

What should I consider when selecting materials for office furniture manufacturing?

Consider three main factors: usage intensity, budget, and environment. High-traffic areas need durable materials like HPL laminate or Corian, while private offices can use more cost-effective options. Think about total cost of ownership, not just initial price—quality EGGER boards with good laminate cost more upfront but last twice as long. Also factor in UAE’s climate (heat, humidity, dust) and your brand image requirements. Premium materials like wood veneer suit executive spaces, while engineered boards work perfectly for workstations.

How do solid wood and engineered wood compare in office furniture production?

Solid wood offers premium appearance and can be refinished multiple times, making it ideal for executive furniture. However, it costs 60-80% more and can warp in variable climates. Engineered wood, especially premium brands like EGGER, provides better dimensional stability at lower cost. It won’t warp in UAE’s climate and performs excellently with quality veneer or laminate surfaces. For most commercial applications, engineered wood delivers better value—use it for workstations and functional pieces, saving solid wood for high-visibility executive areas.

Which materials are most durable for high-traffic office furniture?

High-pressure laminate (HPL) tops the list for work surfaces—it resists scratches, impacts, heat, and moisture better than most alternatives. Corian solid surfaces offer similar durability with the bonus of repairability. For frames, powder-coated steel provides maximum strength and longevity. Commercial-grade fabrics (30,000+ Martindale rubs) or quality vinyl work best for seating. The winning combination: steel or aluminum frames, HPL or Corian surfaces, and quality engineered wood cores from manufacturers like EGGER.

How does the UAE climate influence material choice for office furniture?

UAE’s heat, humidity fluctuations, and dust demand specific considerations. Choose materials with proper moisture content adjustment and UV-resistant finishes to prevent fading and warping. EGGER boards handle humidity variations better than standard options. Specify E0/E1 rated materials to prevent VOC off-gassing in sealed, air-conditioned offices. Smooth, sealed surfaces (laminate, powder-coated metal, properly finished wood) resist dust better than porous materials and need less maintenance—crucial in Dubai’s sandy environment.

What certifications should I look for when choosing furniture materials?

Priority certifications include FSC or PEFC for sustainable wood sourcing, and E1 or E0 ratings for low formaldehyde emissions in engineered boards. Premium manufacturers like EGGER provide full documentation for these standards. Also check for low-VOC certifications on finishes and adhesives, especially for LEED projects. For fabrics, look for Martindale test ratings above 30,000 double rubs and appropriate fire safety certifications. Always request actual certification documents—if suppliers can’t provide them, consider it a quality red flag.

Executive Desk

Executive Desk

Workstation Desk

Workstation Desk

Reception Desk

Reception Desk

Computer Standing Desks

Computer Standing Desks

Height Adjustable Desk

Height Adjustable Desk

Office Sofas

Office Sofas

Carpet Tiles

Carpet Tiles

Wooden Flooring

Wooden Flooring

Conference Table

Conference Table

Folding Table

Folding Table

Round Meeting Table

Round Meeting Table

Coffee Table

Coffee Table

Pedestal Drawers

Pedestal Drawers

Low Cabinets

Low Cabinets

High Cabinets

High Cabinets

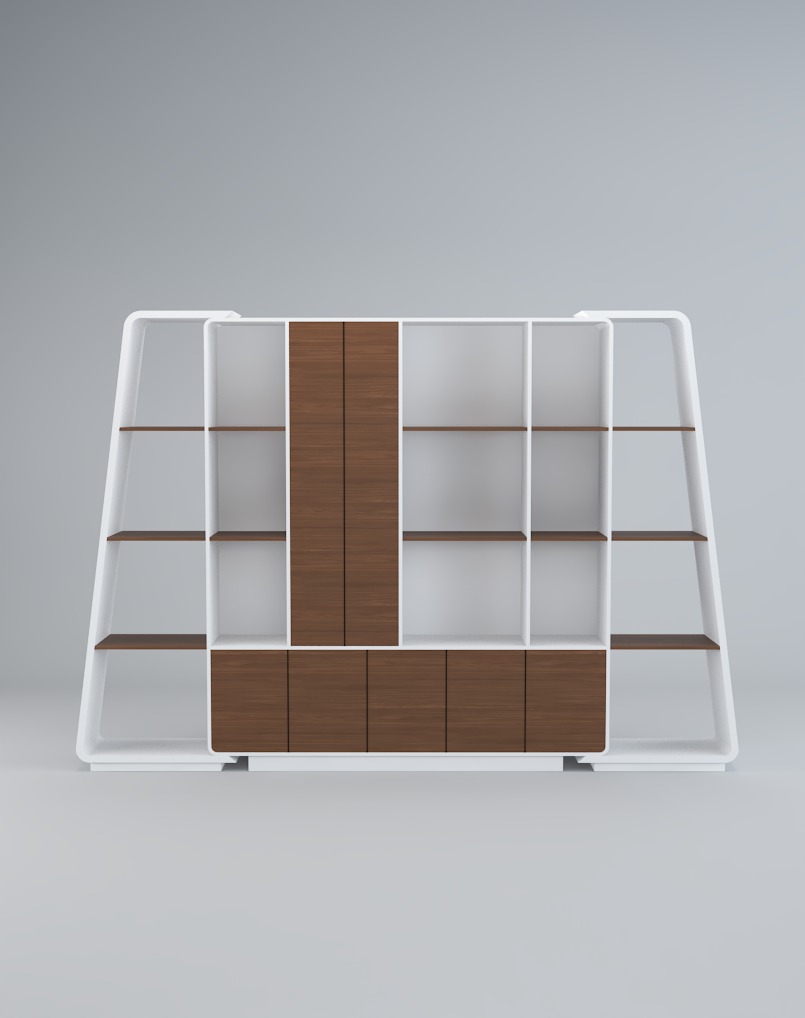

Display Storage Cabinets

Display Storage Cabinets

TV Units And Cabinets

TV Units And Cabinets